I-Kima Chemical ibonwa njengethembekileUmphakeli we-HPMCizithasiselo zodaka lwengxube eyomile, iHydroxypropyl Methylcellulose (HPMC) ivamise ukusetshenziswa njengesithako esiyisihluthulelo sezithasiselo zodaka ezomile zengxube. I-Kima Chemical yaziwa ngokuzibophezela kwayo kwikhwalithi kanye nokuqanjwa kabusha embonini yamakhemikhali ye-dry mix mortar additives.

Udaka olomile oluxubile, olubuye lwaziwe ngokuthi udaka olomile, luyingxube yenhlanganisela ecolekileyo, usimende, izithasiselo, nezinye izithako ezihlanganiswa ngokunembile ukuze zihlangabezane nezidingo ezithile zohlelo lokusebenza. Kuyimpahla yokwakha eguquguqukayo esetshenziswa kumaphrojekthi wokwakha ahlukahlukene, ukusuka endaweni yokuhlala kuye kwezimboni, ngenxa yokusebenziseka kwayo nokungaguquguquki. Lokhu kwakhiwa kodaka olomile oluxubile kudlala indima ebalulekile ekunqumeni izakhiwo zodaka, ukusebenza, nokufaneleka kokusetshenziswa okuthile.

Sizohlolisisa ubunkimbinkimbi bokwakhiwa kodaka olomile, sihlole izingxenye ezihlukahlukene, imisebenzi yazo, nokuthi ziwuthinta kanjani umkhiqizo wokugcina. Sizophinde sixoxe ngokubaluleka kokulawula ikhwalithi futhi sinikeze ithebula elinemininingwane echaza ukwakheka kodaka olomile oluvamile lwezinhlelo zokusebenza ezahlukene.

Okuqukethwe

1. Isingeniso

2. Izingxenye Zodaka Oluxubile Elomile

2.1. I-Fine Aggregate

2.2. Izibophezelo Zesimende

2.3. Izithasiselo

2.4. Amanzi

3. Inqubo Yokwakha

4. Izici Ezithinta Ukwakhiwa

4.1. Izidingo Zohlelo

4.2. Izimo Zemvelo

4.3. Izindleko Ukucatshangelwa

5. Ukulawulwa Kwekhwalithi

5.1. Ukuhlola nokuhlaziya

5.2. Ukuvumelana kwe-Batch-to-Batch

6. Ukwakhiwa Kodaka Okuvamile Okuxubile

6.1. I-Masonry Mortar

6.2. I-Plaster Mortar

6.3. I-Tile Adhesive

6.4. Udaka Lokuzilinganisa

6.5. Lungisa Udaka

6.6. I-Insulation Mortar

7. Isiphetho

8. Izikhombo

1. Isingeniso

Udaka oluxubile olomileiyinhlanganisela pre-ixutshwe izithako ezihlukahlukene ezisetshenziswa izicelo zokwakha. Iqeda isidingo sokuxuba endaweni futhi inikeza ikhwalithi engaguquki, okwenza kube ukukhetha okudumile embonini yezokwakha. Ukwakhiwa kodaka olomile oluxubile kuyinqubo ebalulekile eqinisekisa ukuthi udaka luhlangabezana nezidingo ezithile zokusetshenziswa okuhlosiwe.

2.Izingxenye ze-Dry Mixed Mortar

| Isithako | Umsebenzi | Amaphesenti ngesisindo |

| I-Portland Cement | Isibopho | [40%-50] |

| Isihlabathi (Kuhle) | Isigcwalisi/Izihlanganisi | [30%-50%] |

| Eluhlaza | Ithuthukisa Ukusebenza Nokuvumelana nezimo | [20%-30%] |

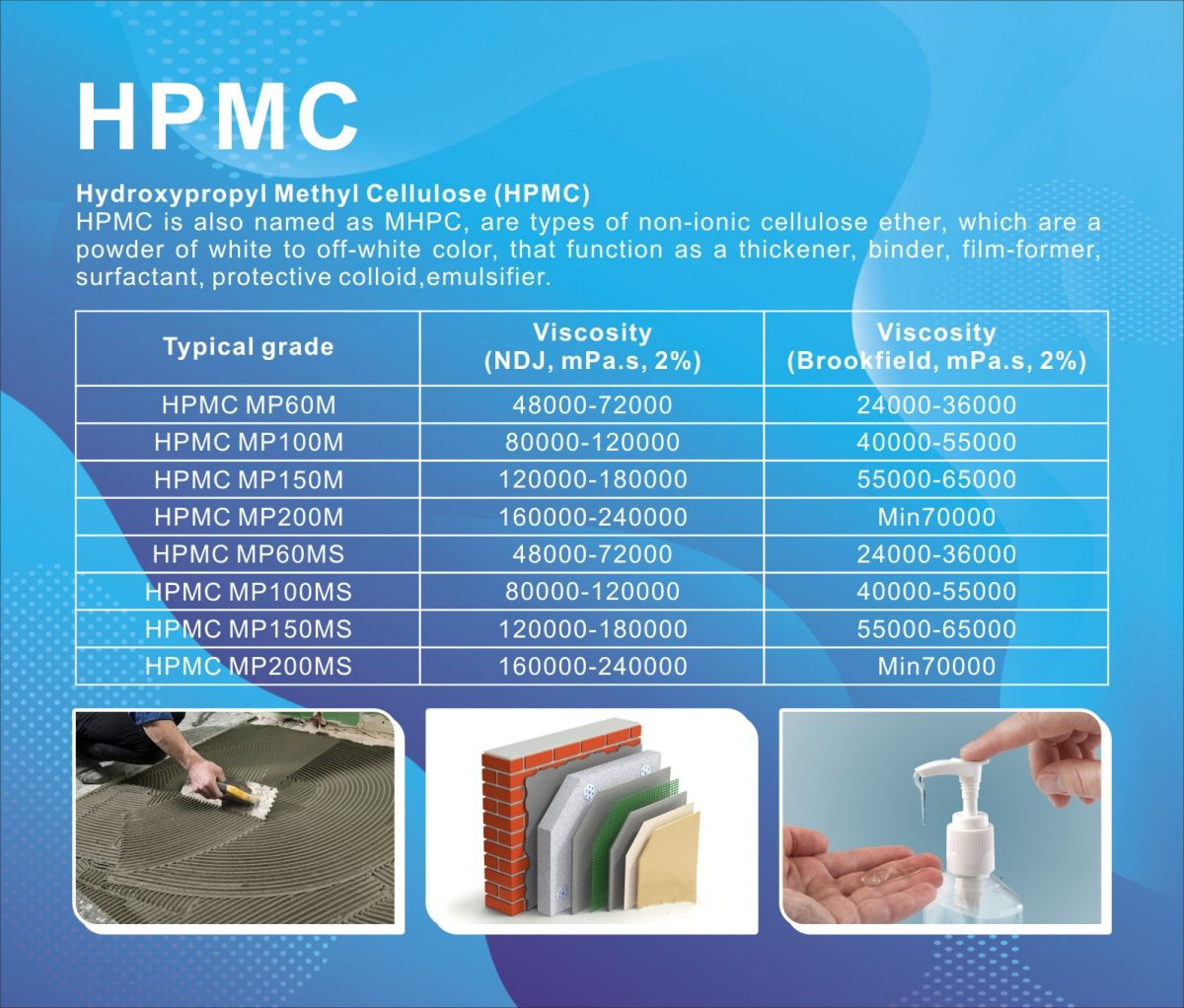

| I-Cellulose Ether | I-ejenti Yokugcina Amanzi | [0.4% ] |

| Izithasiselo zePolymer | Ithuthukisa Ukunamathela kanye Nokuvumelana nezimo | [1.5%] |

| Izingulube | Yengeza Umbala (uma kudingeka) | [0.1%] |

Udaka oluxubekile olomile luqukethe izingxenye ezimbalwa ezibalulekile, ngayinye enendima eyingqayizivele engxubeni. Lezi zingxenye zifaka ukuhlanganisa okuhle, izibophezelo zikasimende, izithasiselo, namanzi.

2.1. I-Fine Aggregate

I-aggregate emihle, ngokuvamile isihlabathi, iyingxenye ebalulekile yodaka olomile oluxubile. Ihlinzeka ngevolumu futhi isebenze njengesigcwalisi, ithuthukisa ukusebenza kodaka futhi yehlise inani lempahla kasimende edingekayo. Usayizi wezinhlayiyana nokusatshalaliswa kweqoqo elihle lithonya kakhulu izici zodaka, njengamandla nokuqina.

2.2. Izibophezelo Zesimende

Izibophezelo zikasimende zinesibopho sokuhlinzeka ngokubumbana namandla odaka. Izibophezelo ezivamile zihlanganisa usimende wase-Portland, usimende abahlanganisiwe, nezinye izibophezelo ze-hydraulic. Uhlobo nenani le-binder elisetshenziswe ekwakhiweni linquma amandla odaka nezici zokusetha.

2.3. Izithasiselo

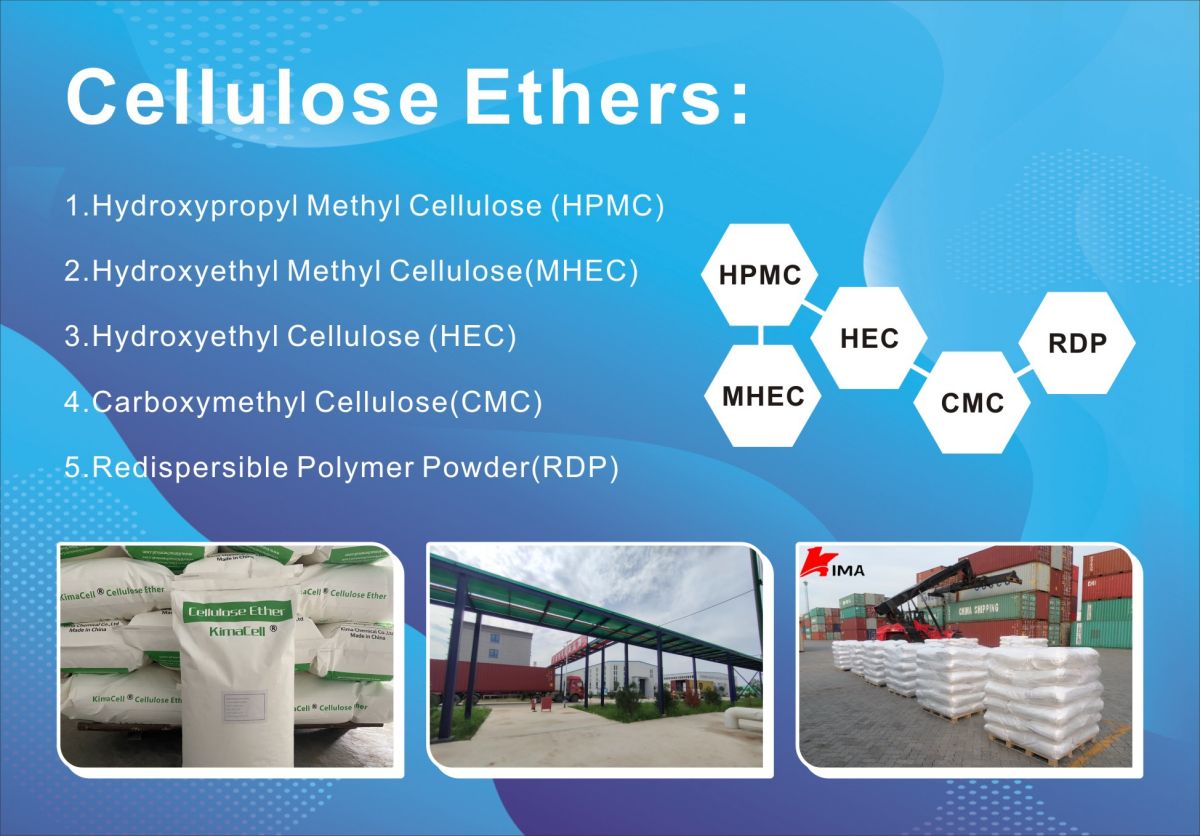

Izithasiselo zisetshenziselwa ukuguqula nokuthuthukisa izakhiwo zodaka olomile oluxubile. Lokhu kungafaka izisheshisi ze-cellulose ethers, retarders, plasticizers, air-entraining agents, nokunye. Izithasiselo zengezwa ngamanani amancane uma kuqhathaniswa kodwa zinomthelela omkhulu ekusebenzeni kodaka, isikhathi sokusetha, nokusebenza ngaphansi kwezimo ezihlukene.

2.4. Amanzi

Amanzi ayingxenye ebalulekile eyenza kube lula ukuxutshwa kwezithako ezomile, okuzivumela ukuthi zenze unamathisele osebenzayo. Isilinganiso samanzi nosimende sibalulekile, njengoba sithinta ukuvumelana kodaka, isikhathi sokusetha, nokusebenza kukonke.

3. Inqubo Yokwakha

Ukwakhiwa kodaka olomile oluxubile kuhilela ukukala ngokucophelela nokuxuba izingxenye ngezilinganiso ezifanele. Inqubo iqala ngokukhethwa kwezinto zokusetshenziswa, okuhlanganisa nokukhetha isamba esihle, izibophezelo zikasimende, izithasiselo, namanzi. Uma izinto sezikhethiwe, zihlanganiswa ngokuvumelana neresiphi oyifunayo.

Izingxenye ezomile (inhlanganisela emihle kanye nezibophezelo zikasimende) ziqala zixutshwe ukuze kuzuzwe ukuhlangana okulinganayo. Ngemva kwalokho, izithasiselo namanzi kufakwa kule ngxube. Inqubo yokuxuba ingase ihluke kuye ngokuthi ukwakheka okuqondile kanye nemishini esetshenzisiwe. Ukuxuba okufanele kubalulekile ukuze kuqinisekiswe ukusatshalaliswa okufanayo kwazo zonke izingxenye, okuthinta ngokuqondile izinga nokusebenza kodaka.

4. Izici Ezithinta Ukwakhiwa

Ukwakhiwa kodaka olomile oluxubile kuthonywa izici ezimbalwa, okuhlanganisa izidingo zokusetshenziswa, izimo zemvelo, nokucatshangelwa kwezindleko.

4.1. Izidingo Zohlelo

Amaphrojekthi wokwakha ahlukene anezidingo ezihlukene zodaka olomile oluxubile. Izinto ezinjengamandla, ukuqina, isikhathi sokusetha, nombala kungase kwehluke ngokusekelwe kuhlelo lokusebenza. Amafomula ayalungiswa ukuze ahlangabezane nalezi zidingo ezithile. Isibonelo, udaka olusetshenziswa ekwakhiweni kwamatshe ludinga izakhiwo ezihlukile kunodaka olusetshenziswa ekufakweni kwamathayili.

4.2. Izimo Zemvelo

Izimo zemvelo, njengezinga lokushisa kanye nomswakama, zingaba nomthelela enqubweni yokwakheka. Lezi zici zithinta isikhathi sokumisa udaka nokusebenza. Ezimweni ezimbi kakhulu, ukwakheka okukhethekile kungase kudingeke ukuze kuqinisekiswe ukusebenza kahle kodaka.

4.3. Izindleko Ukucatshangelwa

Izindleko zezinto kanye nenqubo yokukhiqiza iyonke ingaba nomthelela ezinqumweni zokwakhiwa. Ukulungisa ukwakheka ukuze kuthuthukiswe ukusebenza kahle kwezindleko kuyilapho kugcinwa ukusebenza kuwukucatshangelwa okubalulekile kubakhiqizi.

5. Ukulawulwa Kwekhwalithi

Ukulawulwa kwekhwalithi kuyisici esibalulekile sokukhiqiza udaka olomile oluxubile. Ukuqinisekisa ikhwalithi yomkhiqizo engaguquki kubalulekile ukuze kuhlangatshezwane namazinga emboni kanye nokulindelwe ngamakhasimende.

5.1. Ukuhlola nokuhlaziya

Abakhiqizi benza izivivinyo ezihlukahlukene futhi bahlaziye kukho kokubili izinto zokusetshenziswa kanye nomkhiqizo wokugcina wodaka. Lokhu kuhlola kuhlola izakhiwo ezifana namandla acindezelayo, amandla okunamathela, ukusebenza, nokuqina. Ukulungiswa kokwakheka kungase kudingeke ngokusekelwe emiphumeleni yokuhlolwa.

5.2. Ukuvumelana kwe-Batch-to-Batch

Ukugcina ukungaguquguquki ukusuka kwelinye iqoqo kuye kwelinye kubalulekile ekulawuleni ikhwalithi. Ukuchezuka ekwakhiweni kungaholela ekusebenzeni komkhiqizo okungahambisani. Izinyathelo eziqinile zokulawula ikhwalithi zisiza ukugwema ukungqubuzana okunjalo.

6. Ukwakhiwa Kodaka Okuvamile Okuxubile

Izicelo ezehlukene ezakhiweni zidinga ukwakheka kodaka oluthile. Nazi ezinye izindlela ezivamile zodaka oluxubekile oluxubile kanye nezakhiwo zalo ezibalulekile:

6.1. I-Masonry Mortar

I-masonry mortar isetshenziselwa ukwakhiwa kwezitini noma i-block. Ngokuvamile iqukethe isihlabathi, usimende, futhi ngezinye izikhathi umcako. Ukwakhiwa kuklanyelwe ukuhlinzeka ngokusebenza okuhle, ukunamathela okuqinile, nokumelana nesimo sezulu.

6.2. I-Plaster Mortar

Udaka lwe-Plaster lusetshenziselwa ukuplasta kwangaphakathi nangaphandle kwezindonga nophahla. Yenzelwe ukunikeza isiphetho esibushelelezi nesihlala isikhathi eside. Izithasiselo ezifana nama-retarders zingase zisetshenziselwe ukwelula isikhathi sokusetha sokufaka ukhonkolo.

6.3. I-Tile Adhesive

Udaka olunamathelayo lwethayela lwenzelwe ukunamathisela amathayela ezindaweni ezahlukahlukene. Kudinga ukunamathela okuqinile nokusebenza okuhle kakhulu. Izithasiselo ze-polymer zivame ukufakwa ukuze kuthuthukiswe ukuhlangana nokuvumelana nezimo.

6.4. Udaka Lokuzilinganisa

Udaka oluzilinganisa lusetshenziselwa ukwakha izindawo ezisezingeni kuma-substrates angalingani. Igeleza kalula futhi izileveli ngokwayo, iqinisekisa ukushelela nokuqeda. Izithasiselo ezifana nama-superplasticizers zisetshenziselwa ukufeza izakhiwo ezifiselekayo zokugeleza.

6.5. Lungisa Udaka

Udaka lokulungisa lwenzelwa ukuphetshwa kanye nokulungisa ukhonkolo owonakele noma izindawo eziphakeme zamatshe. Inikeza amandla aphezulu kanye nokuhlangana okuhle kakhulu ku-substrate ekhona. I-Corrosion inhibitors ingase yengezwe ukuze kuqiniswe ukuqina.

6.6. I-Insulation Mortar

I-insulation mortar isetshenziswa ezinhlelweni zokufakelwa kwe-thermal zangaphandle (ETICS) ukunamathisela amabhodi okufakwa ezindongeni. Inezici ezithile zokuqinisekisa ukusebenza okushisayo kwe-insulation. Ama-aggregate angasindi avame ukufakwa ukuze kuncishiswe ukudluliswa kokushisa.

7. Isiphetho

Ukwakhiwa kodaka oluxutshwe okomile kuyinqubo eyinkimbinkimbi ehlanganisa inhlanganisela enembile yenhlanganisela enhle, izibophezelo zikasimende, izithasiselo, namanzi ukuze kudalwe into yokwakha ehambisana nezinhlelo zokusebenza ezithile. Ukuqonda indima yengxenye ngayinye nokucabangela izici ezifana nezidingo zohlelo lokusebenza, izimo zemvelo, nezindleko kubalulekile ekukhiqizeni udaka olomile oluxubile lwekhwalithi ephezulu. Izinyathelo zokulawula ikhwalithi ziqinisekisa ukusebenza komkhiqizo okungaguquki futhi zihlangabezana namazinga omkhakha. Ukusetshenziswa kokwakheka kodaka olomile okuxubile kusabalele ezinhlelweni zokwakha ezahlukahlukene, kusukela ekuqoqweni kwamatshe kanye ne-plastering kuya kuma-adhesive amathayili kanye nezinhlelo zokufakelwa, okugqamisa ukubaluleka kwayo embonini yesimanje yokwakha.

8. Izikhombo

Sicela uqaphele ukuthi ithebula eliqukethe ukwakheka kwedaka elomile elixutshiwe lezinhlelo zokusebenza ezihlukahlukene alifakiwe kule mpendulo ngenxa yobubanzi balo. Uma ungathanda ithebula elinemininingwane, sicela unikeze imininingwane ethile mayelana nokwakheka onentshisekelo kukho, futhi ngingakusiza ekudaleni ithebula elisuselwe kulolo lwazi.

Isikhathi sokuthumela: Nov-10-2023