Kima Chemical inozivikanwa seyakavimbikaHPMC mutengesiyedry mix mortar additives, Hydroxypropyl Methylcellulose (HPMC) inowanzoshandiswa sechinhu chakakosha mune yakaoma musanganiswa dhaka additives. Kima Chemical inozivikanwa nekuzvipira kwayo kumhando uye hunyanzvi mune yakaoma musanganiswa dhaka rekuwedzera makemikari indasitiri.

Dry yakasanganiswa dhaka, inozivikanwawo sedhaka rakaoma, musanganiswa weyakaomeswa aggregate, simende, zvekuwedzera, uye zvimwe zvinongedzo zvinonyatso sanganiswa kuti zvisangane nezvinodiwa zvekushandisa. Icho chinhu chakasiyana-siyana chekuvaka chinoshandiswa mumapurojekiti akasiyana ekuvaka, kubva pakugara kusvika kumaindasitiri, nekuda kwekureruka kwayo uye kuenderana. Uku kuumbwa kwedhaka rakaoma rakasanganiswa kunoita basa rakakosha pakuona zvimiro zvedhaka, kuita, uye kukodzera kweimwe application.

Isu tichaongorora mukati mekuoma kwakaoma kwakasanganiswa dhaka kugadzirwa, tichiongorora zvakasiyana zvikamu, mabasa azvo, uye maitiro azvinoita chigadzirwa chekupedzisira. Tichakurukurawo kukosha kwekutonga kwemhando uye nekupa tafura yakadzama inotsanangura zvakajairika yakaoma yakasanganiswa dhaka maumbirwo ezvishandiso zvakasiyana.

Zviri Mukati

1. Nhanganyaya

2. Zvikamu zveDry Mixed Mortar

2.1. Fine Aggregate

2.2. Cementitious Binders

2.3. Additives

2.4. Mvura

3. The Formulation Process

4. Zvinhu Zvinokanganisa Kugadzira

4.1. Zvinodiwa Zvekushandisa

4.2. Environmental Conditions

4.3. Kufunga Kwemari

5. Kudzora Kwehutano

5.1. Kuedzwa uye Analysis

5.2. Batch-to-Batch Consistency

6. Common Dry Mixed Mortar Formulations

6.1. Masonry Mortar

6.2. Plaster Mortar

6.3. Tile Adhesive

6.4. Self-Leveling Mortar

6.5. Repair Mortar

6.6. Insulation Mortar

7. Mhedziso

8. References

1. Nhanganyaya

Dry yakasanganiswa dhakandeye pre-musanganiswa musanganiswa wezvakasiyana-siyana zvinoshandiswa mukuvaka zvikumbiro. Iyo inobvisa kudiwa kwekusanganiswa kwepa-saiti uye inopa hunoenderana mhando, ichiita iyo yakakurumbira sarudzo muindasitiri yekuvaka. Kugadzirwa kwedhaka rakaoma rakasanganiswa idanho rakakosha rinoita kuti dhaka rizadzise izvo zvinodikanwa zvechishuwo chakatarisirwa.

2.Zvikamu zveDry Mixed Mortar

| Ingredient | Function | Percentage by Weight |

| Portland Cement | Binder | [40%-50] |

| Jecha (Yakanaka) | Filler/Aggregates | [30%-50%] |

| Lime | Inowedzera Kushanda uye Kuchinja | [20%-30%] |

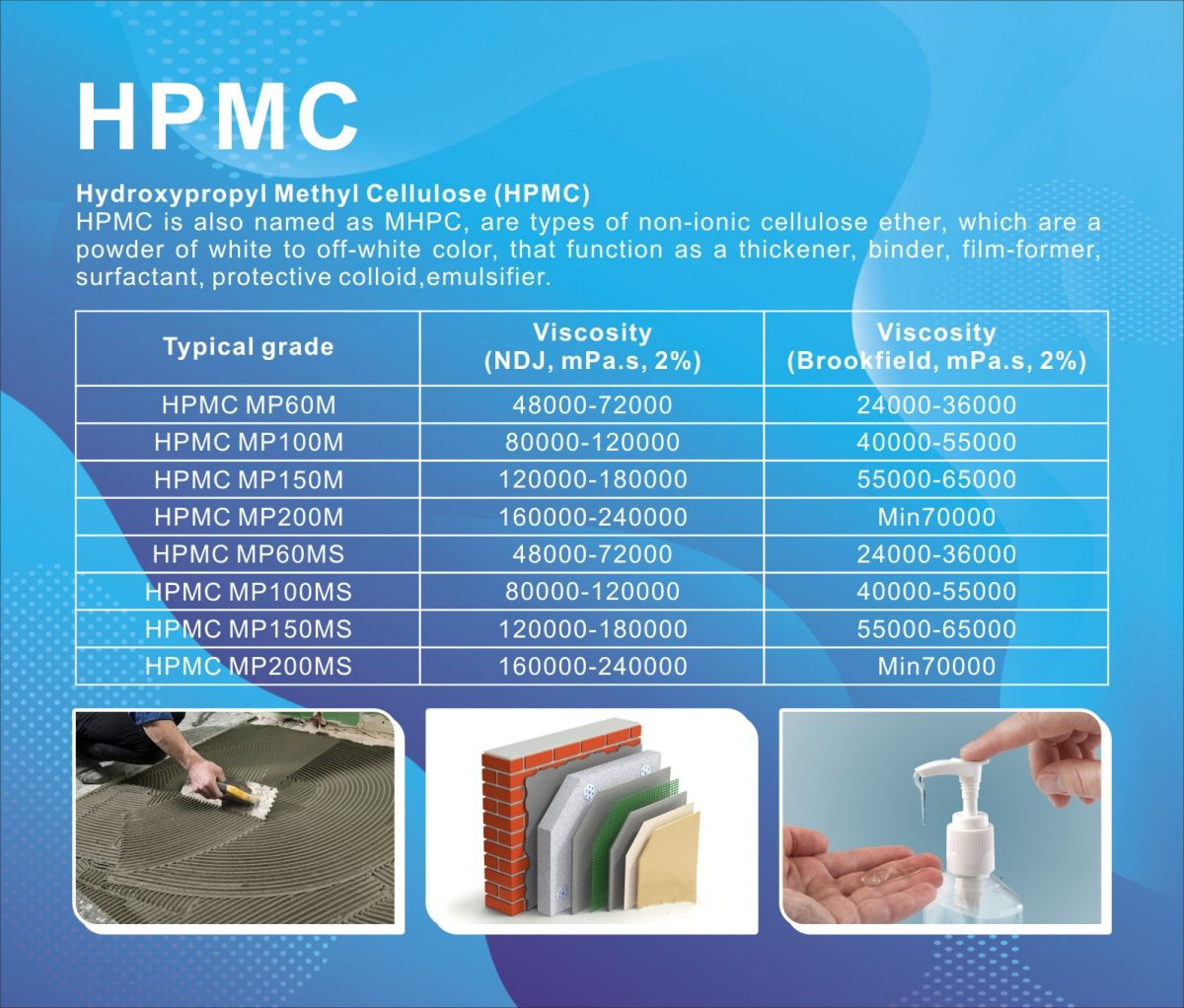

| Cellulose Ether | Mvura Kuchengetedza Mumiririri | [0.4% ] |

| Polymer Additives | Inovandudza Adhesion uye Flexibility | [1.5%] |

| Pigments | Inowedzera Ruvara (kana zvichidikanwa) | [0.1%] |

Dry yakasanganiswa dhaka ine akati wandei akakosha zvikamu, chimwe nechimwe chine basa rakasiyana mumusanganiswa. Izvi zvikamu zvinosanganisira akakwana aggregate, cementitious binders, additives, uye mvura.

2.1. Fine Aggregate

Fine aggregate, kazhinji jecha, chinhu chakakosha chevhu rakaoma rakasanganiswa dhaka. Inopa vhoriyamu uye inoita senge yekuzadza, inosimudzira kushanda kwedhaka uye kuderedza huwandu hwesimende zvinhu zvinodiwa. Saizi yechidimbu uye kugovera kweiyo yakaunganidzwa inokonzeresa zvakanyanya zvimiro zvedhaka, sesimba nekusimba.

2.2. Cementitious Binders

Cementitious binders vane basa rekupa kubatana uye simba kune dhaka. Zvisungo zvakajairika zvinosanganisira Portland simende, masimende akasanganiswa, uye mamwe ma hydraulic binder. Rudzi uye huwandu hwebhainda rinoshandiswa mukugadzira zvinoraira kusimba kwedhaka uye maitiro ekuseta.

2.3. Additives

Zviwedzerwa zvinoshandiswa kugadzirisa uye kuwedzera zvimiro zveiyo yakaoma yakasanganiswa dhaka. Izvi zvinogona kusanganisira cellulose ethers accelerators, retarders, plasticizers, air-entraining agents, nezvimwe. Zvinowedzerwa zvinowedzerwa muhuwandu hudiki asi zvine simba guru pakushanda kwedhaka, nguva yekuisa, uye kushanda pasi pemamiriro akasiyana.

2.4. Mvura

Mvura chinhu chakakosha chinogonesa kusanganiswa kwezvinhu zvakaoma, zvichiita kuti vagadzire paste inoshanda. Iyo yemvura-kune-simende reshiyo yakakosha, nekuti inokanganisa kuenderana kwedhaka, nguva yekumisikidza, uye kuita kwese.

3. The Formulation Process

Kugadzirwa kwedhaka rakaoma rakasanganiswa rinosanganisira kunyatsoyera uye kusanganisa zvikamu muzvikamu zvakakodzera. Maitiro acho anotanga nekusarudzwa kwezvinhu zvakabikwa, zvinosanganisira kusarudzwa kweiyo yakanaka aggregate, cementitious binders, additives, uye mvura. Kana zvinhu zvasarudzwa, zvinosanganiswa maererano nekamukira inodiwa.

Iyo yakaoma components (fine aggregate uye cementitious binders) zvinotanga zvakasanganiswa kuti zviwane homogeneous musanganiswa. Mushure mezvo, zvinowedzera uye mvura zvinosanganiswa mumusanganiswa. Iyo yekusanganisa maitiro inogona kusiyana zvichienderana neyakagadzikwa uye midziyo inoshandiswa. Kusanganisa kwakakodzera kwakakosha kuti uve nechokwadi chekugovera kwakafanana kwese zvikamu, izvo zvinokanganisa zvakananga kunaka kwedhaka uye kuita.

4. Zvinhu Zvinokanganisa Kugadzira

Kugadzirwa kwedhaka rakaoma rakasanganiswa rinopesvedzerwa nezvinhu zvakati wandei, zvinosanganisira zvinodiwa zvekushandisa, mamiriro ezvakatipoteredza, uye kufunga kwemitengo.

4.1. Zvinodiwa Zvekushandisa

Mapurojekiti ekuvaka akasiyana ane zvinodiwa zvakasiyana kune yakaoma yakasanganiswa dhaka. Zvinhu zvakaita sesimba, kusimba, nguva yekumisikidza, uye ruvara zvinogona kusiyana zvichienderana nekushandisa. Magadzirirwo anogadziridzwa kuti aenderane nezvinodiwa chaizvo izvi. Semuenzaniso, dhaka rinoshandiswa mukuvaka masonry rinoda zvivakwa zvakasiyana pane dhaka rinoshandiswa mukuisa mataira.

4.2. Environmental Conditions

Mamiriro ezvakatipoteredza, akadai sekushisa uye humidity, anogona kukanganisa maitiro ekugadzira. Zvinhu izvi zvinokanganisa nguva yekugadzika kwedhaka uye kushanda. Mumamiriro ezvinhu akanyanya, kugadzirwa kwakakosha kunogona kudikanwa kuti ive nechokwadi chekuita kwedhaka.

4.3. Kufunga Kwemari

Mutengo wezvishandiso uye maitiro ese ekugadzira anogona kukanganisa sarudzo dzekugadzira. Kugadzirisa dhizaini kuti uwedzere kudhura-kushanda uku uchichengetedza mashandiro chinhu chakakosha kufunga kune vagadziri.

5. Kudzora Kwehutano

Kudzora kwemhando chinhu chakakosha chekugadzirwa kwedhaka rakaoma rakasanganiswa. Kuve nechokwadi chekuenderana kwemhando yechigadzirwa kwakakosha kuzadzisa zviyero zveindasitiri uye zvinotarisirwa nevatengi.

5.1. Kuedzwa uye Analysis

Vagadziri vanoita bvunzo dzakasiyana siyana uye ongororo pane ese ari maviri ezvigadzirwa uye yekupedzisira yedhaka chigadzirwa. Aya maedzo anoongorora zvivakwa zvakaita sesimba rekumanikidza, simba rekunamatira, kushanda, uye kusimba. Kugadziriswa kwekugadzirisa kunogona kudiwa zvichienderana nemigumisiro yebvunzo.

5.2. Batch-to-Batch Consistency

Kuchengetedza kuenderana kubva kune rimwe batch kuenda kune rimwe kwakakosha pakutonga kwemhando. Kutsauka mukugadzira kunogona kutungamirira kukusaenderana kwechigadzirwa. Matanho akasimba ekudzora maitiro anobatsira kudzivirira kusawirirana kwakadaro.

6. Common Dry Mixed Mortar Formulations

Mashandisirwo akasiyana mukuvaka anoda chaiwo maumbirwo edhaka. Heano mamwe akajairika akaoma akasanganiswa dhaka maumbirwo uye akakosha zvimiro:

6.1. Masonry Mortar

Masonry mortar inoshandiswa mukuvaka zvidhinha kana block block. Iyo inowanzo sanganisira jecha, simende, uye dzimwe nguva lime. Iko kuumbwa kwakagadzirirwa kupa kushanda kwakanaka, kunamatira kwakasimba, uye kuramba kune mamiriro ekunze.

6.2. Plaster Mortar

Plaster mortar inoshandiswa kupurasita mukati nekunze kwemadziro uye sirin'i. Yakagadzirwa kuti ipe kupera kwakatsetseka uye kwakasimba. Zviwedzerwa senge retarders zvinogona kushandiswa kuwedzera nguva yekumisikidza yekuisa plaster.

6.3. Tile Adhesive

Tile inonamira dhaka yakagadzirirwa kubatanidza mataira kunzvimbo dzakasiyana siyana. Inoda kunamatira kwakasimba uye kushanda zvakanaka. Polymer additives kazhinji inosanganisirwa kusimudzira kubatana uye kuchinjika.

6.4. Self-Leveling Mortar

Kuzvimisa-leveling dhaka rinoshandiswa kugadzira nhanho dzepamusoro pane zvisina kuenzana substrates. Inoyerera zviri nyore uye mazinga pachayo, ichivimbisa yakatsetseka uye kunyange kupera. Zvinowedzerwa senge superplasticizers zvinoshandiswa kuzadzisa zvinodiwa kuyerera zvivakwa.

6.5. Repair Mortar

Kugadzirisa dhaka rakagadzirirwa kupeta uye kugadzirisa yakakuvadzwa kongiri kana masonry nzvimbo. Inopa simba rakakwirira uye yakanakisa kubatanidza kune iripo substrate. Corrosion inhibitors inogona kuwedzerwa kuti iwedzere kusimba.

6.6. Insulation Mortar

Insulation dhaka inoshandiswa mune ekunze thermal insulation system (ETICS) kubatanidza mabhodhi ekudzivirira kumadziro. Iine zvivakwa zvakananga kuti ive nechokwadi chekushanda kwekupisa kweiyo insulation. Akareruka akaunganidzwa anowanzo batanidzwa kuderedza kupisa kutamisa.

7. Mhedziso

Dry yakasanganiswa dhaka maumbirwo ibasa rakaoma rinosanganisira kusanganisa kwakaringana kweakarembera, simende mabhainda, ekuwedzera, uye mvura kugadzira chinhu chekuvaka chakagadzirirwa kune chaiwo mashandisirwo. Kunzwisisa basa rechikamu chimwe nechimwe uye kufunga nezvezvinhu zvakaita sezvinodiwa zvekushandisa, mamiriro ekunze, uye mutengo wakakosha mukugadzira yemhando yepamusoro yakaoma yakasanganiswa dhaka. Matanho ekudzora emhando inovimbisa kuenderana kwechigadzirwa kuita uye kusangana nemaindasitiri zviyero. Iko kushandiswa kwekuoma kwakasanganiswa dhaka maumbirwo kwakapararira mune zvakasiyana-siyana zvekuvaka zvikumbiro, kubva kune masonry uye plastering kune mataira adhesive uye insulation masisitimu, kuratidza kukosha kwayo muindasitiri yekuvaka yemazuva ano.

8. References

Tapota cherechedza kuti tafura ine maumbirwo edhaka akaomeswa ezvishandiso zvakasiyana-siyana yasiiwa kubva mumhinduro iyi nekuda kwekuwanda kwayo. Kana iwe uchida tafura yakadzama, ndapota ipa zvakanangana nezve maumbirwo auri kufarira, uye ini ndinogona kukubatsira mukugadzira tafura zvichienderana neruzivo irworwo.

Nguva yekutumira: Nov-10-2023