Ana gane Kima Chemical azaman abin dogaroHPMC mai bayarwana bushe mix turmi Additives, Hydroxypropyl Methylcellulose (HPMC) yawanci amfani da matsayin key sashi a bushe mix turmi Additives. Kima Chemical sananne ne don sadaukarwar sa ga inganci da ƙima a cikin busassun busassun kayan hada kayan sinadarai.

Busassun turmi mai gauraya, wanda kuma aka sani da busasshen turmi, cakuɗe ne na tara mai kyau, siminti, ƙari, da sauran abubuwan da aka haɗa su daidai don biyan takamaiman buƙatun aikace-aikacen. Kayan gini iri-iri ne da ake amfani da shi a cikin ayyukan gine-gine daban-daban, daga wurin zama zuwa masana'antu, saboda dacewa da daidaito. Wannan tsari na busasshen turmi gauraye yana taka muhimmiyar rawa wajen tantance kaddarorin turmi, aiki, da dacewa da wani takamaiman aikace-aikace.

Za mu zurfafa cikin rikitattun busassun ƙera turmi gauraye, bincika sassa daban-daban, ayyukansu, da yadda suke tasiri samfurin ƙarshe. Za mu kuma tattauna mahimmancin kula da inganci da kuma samar da cikakken tebur wanda ke bayyana busassun gaurayawan turmi na gama gari don aikace-aikace daban-daban.

Teburin Abubuwan Ciki

1. Gabatarwa

2. Abubuwan Busassun Ganyen Turmi

2.1. Tari mai kyau

2.2. Siminti Binders

2.3. Additives

2.4. Ruwa

3. Tsarin Samfura

4. Abubuwan Da Suka Shafi Tsarin Halitta

4.1. Bukatun Aikace-aikace

4.2. Yanayin Muhalli

4.3. La'akarin Farashi

5. Quality Control

5.1. Gwaji da Bincike

5.2. Daidaiton Tsari-zuwa-Batch

6. Na kowa Busassun Gauraye Turmi Formulations

6.1. Masonry Mortar

6.2. Turmi Plaster

6.3. Tile Adhesive

6.4. Turmi Mai Matsayin Kai

6.5. Gyara Turmi

6.6. Turmi mai rufi

7. Kammalawa

8. Magana

1. Gabatarwa

Bushewar turmi mai gaurayawani hadadden hadadden nau'in sinadarai ne daban-daban da ake amfani da su wajen aikace-aikacen gini. Yana kawar da buƙatar haɗakarwa akan rukunin yanar gizon kuma yana ba da daidaiton inganci, yana mai da shi mashahurin zaɓi a cikin masana'antar gini. Ƙirƙirar busassun busassun turmi mai gauraya tsari ne mai mahimmanci wanda ke tabbatar da turmi ya cika takamaiman buƙatun aikace-aikacen da aka yi niyya.

2.Abubuwan Busassun Ganyen Turmi

| Sinadarin | Aiki | Kashi na Nauyi |

| Siminti na Portland | Daure | [40% -50] |

| Yashi (Lafiya) | Filler/Aggregates | [30-50%] |

| Lemun tsami | Yana Haɓaka Aiki da Sassautu | [20-30%] |

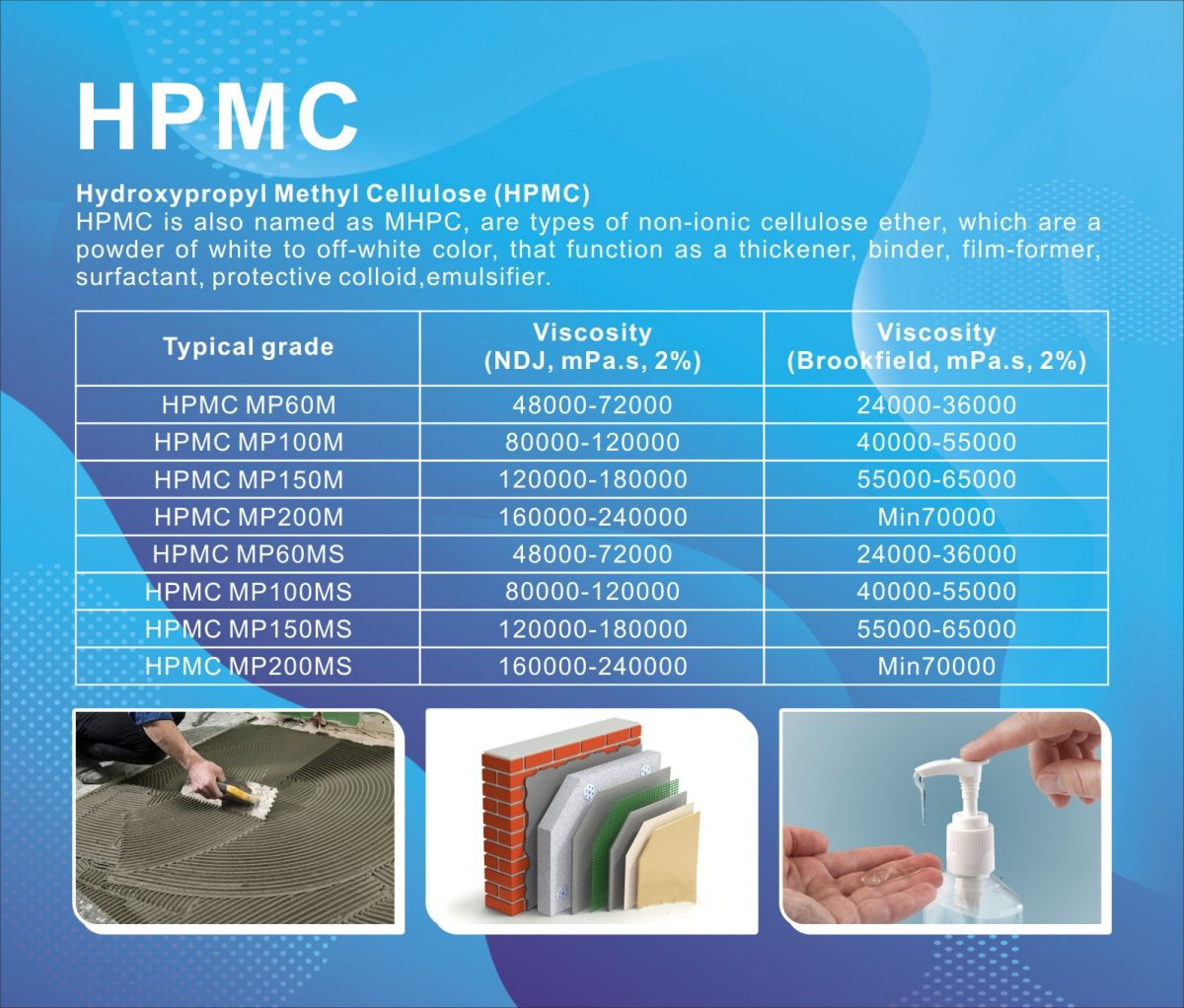

| Cellulose ether | Wakilin Riƙe Ruwa | [0.4%] |

| Polymer Additives | Yana inganta Adhesion da sassauci | [1.5%] |

| Alamu | Yana Ƙara Launi (idan an buƙata) | [0.1%] |

Ganyen turmi busassun ya ƙunshi maɓalli da yawa, kowanne yana da rawar musamman a cikin cakuda. Waɗannan abubuwan sun haɗa da tara mai kyau, masu ɗaure siminti, ƙari, da ruwa.

2.1. Tari mai kyau

Kyakkyawan tarawa, sau da yawa yashi, muhimmin abu ne na busasshiyar turmi gauraye. Yana ba da ƙara kuma yana aiki azaman mai cikawa, haɓaka aikin turmi da rage adadin siminti da ake buƙata. Girman barbashi da rarraba tara mai kyau yana tasiri sosai ga kaddarorin turmi, kamar ƙarfi da dorewa.

2.2. Siminti Binders

Masu ɗauren siminti suna da alhakin samar da haɗin kai da ƙarfi ga turmi. Abubuwan ɗaure na gama gari sun haɗa da siminti na Portland, siminti mai gauraya, da sauran masu ɗauren ruwa. Nau'i da adadin abin ɗaure da aka yi amfani da shi a cikin ƙirƙira suna nuna ƙarfin turmi da halayen saiti.

2.3. Additives

Ana amfani da ƙari don gyarawa da haɓaka kaddarorin busassun cakuda turmi. Waɗannan na iya haɗawa da ethers cellulose accelerators, retarders, plasticizers, iska-entraining jamiái, da sauransu. Ana ƙara abubuwan daɗaɗɗa a cikin ƙananan ƙananan yawa amma suna da tasiri mai mahimmanci akan iyawar turmi, saita lokaci, da aiki a ƙarƙashin yanayi daban-daban.

2.4. Ruwa

Ruwa abu ne mai mahimmanci wanda ke sauƙaƙe haɗuwa da busassun sinadaran, yana ba su damar yin manna mai aiki. Matsakaicin ruwa-zuwa siminti yana da mahimmanci, saboda yana shafar daidaiton turmi, saita lokaci, da aikin gabaɗaya.

3. Tsarin Samfura

Ƙirƙirar busasshen turmi gauraye ya ƙunshi auna a hankali da haɗa abubuwan da aka gyara daidai gwargwado. Tsarin yana farawa tare da zaɓin albarkatun ƙasa, gami da zaɓi na tara mai kyau, masu ɗaure siminti, ƙari, da ruwa. Da zarar an zaɓi kayan, ana yin su bisa ga girke-girke da ake so.

Abubuwan busassun busassun (tarin tara mai kyau da masu ɗaure siminti) an fara gauraya su don cimma daidaito iri ɗaya. Bayan haka, an haɗa abubuwan da ake ƙarawa da ruwa a cikin cakuda. Tsarin hadawa na iya bambanta dangane da takamaiman tsari da kayan aikin da aka yi amfani da su. Haɗin da ya dace yana da mahimmanci don tabbatar da rarraba iri ɗaya na duk abubuwan haɗin gwiwa, wanda kai tsaye yana shafar ingancin turmi da aikin.

4. Abubuwan Da Suka Shafi Tsarin Halitta

Ƙirƙirar busasshen turmi gauraye yana tasiri da abubuwa da yawa, gami da buƙatun aikace-aikacen, yanayin muhalli, da la'akarin farashi.

4.1. Bukatun Aikace-aikace

Ayyukan gine-gine daban-daban suna da buƙatu daban-daban don busasshen turmi gauraye. Abubuwa kamar ƙarfi, dorewa, lokacin saita lokaci, da launi na iya bambanta dangane da aikace-aikacen. Ana daidaita tsari don biyan waɗannan takamaiman buƙatu. Misali, turmi da aka yi amfani da shi wajen ginin gini yana buƙatar kaddarori daban-daban fiye da turmi da aka yi amfani da shi wajen girka tayal.

4.2. Yanayin Muhalli

Yanayin muhalli, kamar zafin jiki da zafi, na iya yin tasiri ga tsarin ƙirƙira. Waɗannan abubuwan suna shafar lokacin saita turmi da ƙarfin aiki. A cikin matsanancin yanayi, ƙila a buƙaci ƙira na musamman don tabbatar da aikin turmi da ya dace.

4.3. La'akarin Farashi

Farashin kayan aiki da tsarin samarwa gabaɗaya na iya yin tasiri ga yanke shawara. Daidaita ƙira don haɓaka ƙimar farashi yayin kiyaye aiki yana da mahimmancin la'akari ga masana'antun.

5. Quality Control

Kula da inganci muhimmin al'amari ne na busasshen samar da turmi gauraye. Tabbatar da daidaiton ingancin samfur yana da mahimmanci don biyan matsayin masana'antu da tsammanin abokin ciniki.

5.1. Gwaji da Bincike

Masu kera suna gudanar da gwaje-gwaje daban-daban da nazari akan duka albarkatun ƙasa da samfurin turmi na ƙarshe. Waɗannan gwaje-gwajen suna tantance kaddarorin kamar ƙarfin matsawa, ƙarfin mannewa, iya aiki, da karko. gyare-gyare ga tsari na iya zama dole bisa sakamakon gwajin.

5.2. Daidaiton Tsari-zuwa-Batch

Kula da daidaito daga wannan tsari zuwa wani yana da mahimmanci don sarrafa inganci. Bambance-bambance a cikin tsari na iya haifar da rashin daidaiton aikin samfur. Matakan kula da inganci masu ƙarfi suna taimakawa guje wa irin wannan rashin daidaituwa.

6. Na kowa Busassun Gauraye Turmi Formulations

Aikace-aikace daban-daban a cikin ginin suna buƙatar takamaiman ƙirar turmi. Ga wasu busassun gauraye turmi na gama gari da mahimman kaddarorinsu:

6.1. Masonry Mortar

Ana amfani da turmi mai ma'ana a cikin tubali ko toshe ginin. Yawanci ya ƙunshi yashi, siminti, da kuma lemun tsami. An tsara ƙirar don samar da kyakkyawan aiki, mannewa mai ƙarfi, da juriya ga yanayin yanayi.

6.2. Turmi Plaster

Ana amfani da turmi mai filasta don yin filastar ciki da waje na bango da rufi. An tsara shi don samar da ƙarewa mai santsi da ɗorewa. Ana iya amfani da ƙari kamar masu ɗaukar hoto don tsawaita lokacin saiti don aikace-aikacen filasta.

6.3. Tile Adhesive

An ƙera turmi mai ɗaure tile don liƙa fale-falen fale-falen buraka a sama daban-daban. Yana buƙatar mannewa mai ƙarfi da kyakkyawan aiki. Abubuwan da ake ƙara polymer galibi ana haɗa su don haɓaka haɗin gwiwa da sassauci.

6.4. Turmi Mai Matsayin Kai

Ana amfani da turmi mai daidaita kai don ƙirƙirar saman saman akan madaidaicin ma'auni. Yana gudana cikin sauƙi da matakan kanta, yana tabbatar da santsi kuma har ma ya ƙare. Ana amfani da ƙari irin su superplasticizers don cimma abubuwan da ake so.

6.5. Gyara Turmi

An ƙera turmi na gyare-gyare don yin faci da gyaran simintin da ya lalace ko masonry. Yana ba da ƙarfi mai ƙarfi da kyakkyawan haɗin gwiwa ga abubuwan da ke akwai. Za a iya ƙara masu hana lalata don ingantacciyar dorewa.

6.6. Turmi mai rufi

Ana amfani da turmi mai ɗorewa a cikin tsarin insulation na waje (ETICS) don haɗa allon rufewa zuwa bango. Yana da ƙayyadaddun kaddarorin don tabbatar da aikin thermal na rufin. Ana yawan haɗa tarukan masu nauyi don rage zafi.

7. Kammalawa

Busassun gauraya turmi tsari ne mai rikitarwa wanda ya ƙunshi daidaitaccen haɗin tara mai kyau, masu ɗaure siminti, ƙari, da ruwa don ƙirƙirar kayan gini da aka keɓance da takamaiman aikace-aikace. Fahimtar rawar kowane bangare da la'akari da abubuwa kamar buƙatun aikace-aikacen, yanayin muhalli, da farashi yana da mahimmanci wajen samar da busasshiyar gauraye turmi mai inganci. Matakan kula da ingancin suna tabbatar da daidaiton aikin samfur kuma sun cika ka'idojin masana'antu. Amfani da busassun gauraya turmi ya yadu a aikace-aikacen gine-gine daban-daban, tun daga masonry da plastering zuwa tile da kuma tsarin rufewa, yana nuna mahimmancinsa a masana'antar gine-gine na zamani.

8. Magana

Lura cewa tebur ɗin da ke ɗauke da takamaiman busassun gauraya turmi don aikace-aikace daban-daban an cire shi daga wannan martanin saboda girman yanayinsa. Idan kuna son cikakken tebur, da fatan za ku samar da takamaiman bayanai game da tsarin da kuke sha'awar, kuma zan iya taimaka muku wajen ƙirƙirar tebur bisa wannan bayanin.

Lokacin aikawa: Nuwamba-10-2023