Kima Chemical is recognized as a reliable HPMC supplier of dry mix mortar additives, Hydroxypropyl Methylcellulose (HPMC) is commonly used as a key ingredient in dry mix mortar additives. Kima Chemical is known for its commitment to quality and innovation in the dry mix mortar additives chemical industry.

Dry mixed mortar, also known as dry mortar, is a mixture of fine aggregate, cement, additives, and other ingredients that are precisely blended to meet specific application requirements. It is a versatile construction material used in various building projects, from residential to industrial, due to its convenience and consistency. This formulation of dry mixed mortar plays a crucial role in determining the mortar’s properties, performance, and suitability for a particular application.

We will delve into the intricacies of dry mixed mortar formulation, exploring the various components, their functions, and how they impact the final product. We will also discuss the importance of quality control and provide a detailed table outlining common dry mixed mortar formulations for different applications.

Table of Contents

1. Introduction

2. Components of Dry Mixed Mortar

2.1. Fine Aggregate

2.2. Cementitious Binders

2.3. Additives

2.4. Water

3. The Formulation Process

4. Factors Affecting Formulation

4.1. Application Requirements

4.2. Environmental Conditions

4.3. Cost Considerations

5. Quality Control

5.1. Testing and Analysis

5.2. Batch-to-Batch Consistency

6. Common Dry Mixed Mortar Formulations

6.1. Masonry Mortar

6.2. Plaster Mortar

6.3. Tile Adhesive

6.4. Self-Leveling Mortar

6.5. Repair Mortar

6.6. Insulation Mortar

7. Conclusion

8. References

1. Introduction

Dry mixed mortar is a pre-mixed blend of various ingredients used in construction applications. It eliminates the need for on-site mixing and offers consistent quality, making it a popular choice in the construction industry. The formulation of dry mixed mortar is a critical process that ensures the mortar meets the specific requirements of the intended application.

2. Components of Dry Mixed Mortar

|

Ingredient |

Function |

Percentage by Weight |

| Portland Cement | Binder | [40%-50] |

| Sand (Fine) | Filler/Aggregates | [30%-50%] |

| Lime | Enhances Workability and Flexibility | [20%-30%] |

| Cellulose Ether | Water Retention Agent | [0.4% ] |

| Polymer Additives | Improves Adhesion and Flexibility | [1.5%] |

| Pigments | Adds Color (if required) | [0.1%] |

Dry mixed mortar consists of several key components, each with a unique role in the mixture. These components include fine aggregate, cementitious binders, additives, and water.

2.1. Fine Aggregate

Fine aggregate, often sand, is an essential component of dry mixed mortar. It provides volume and acts as a filler, enhancing the mortar’s workability and reducing the amount of cementitious material required. The particle size and distribution of the fine aggregate significantly influence the mortar’s properties, such as strength and durability.

2.2. Cementitious Binders

Cementitious binders are responsible for providing cohesion and strength to the mortar. Common binders include Portland cement, blended cements, and other hydraulic binders. The type and amount of binder used in the formulation dictate the mortar’s strength and setting characteristics.

2.3. Additives

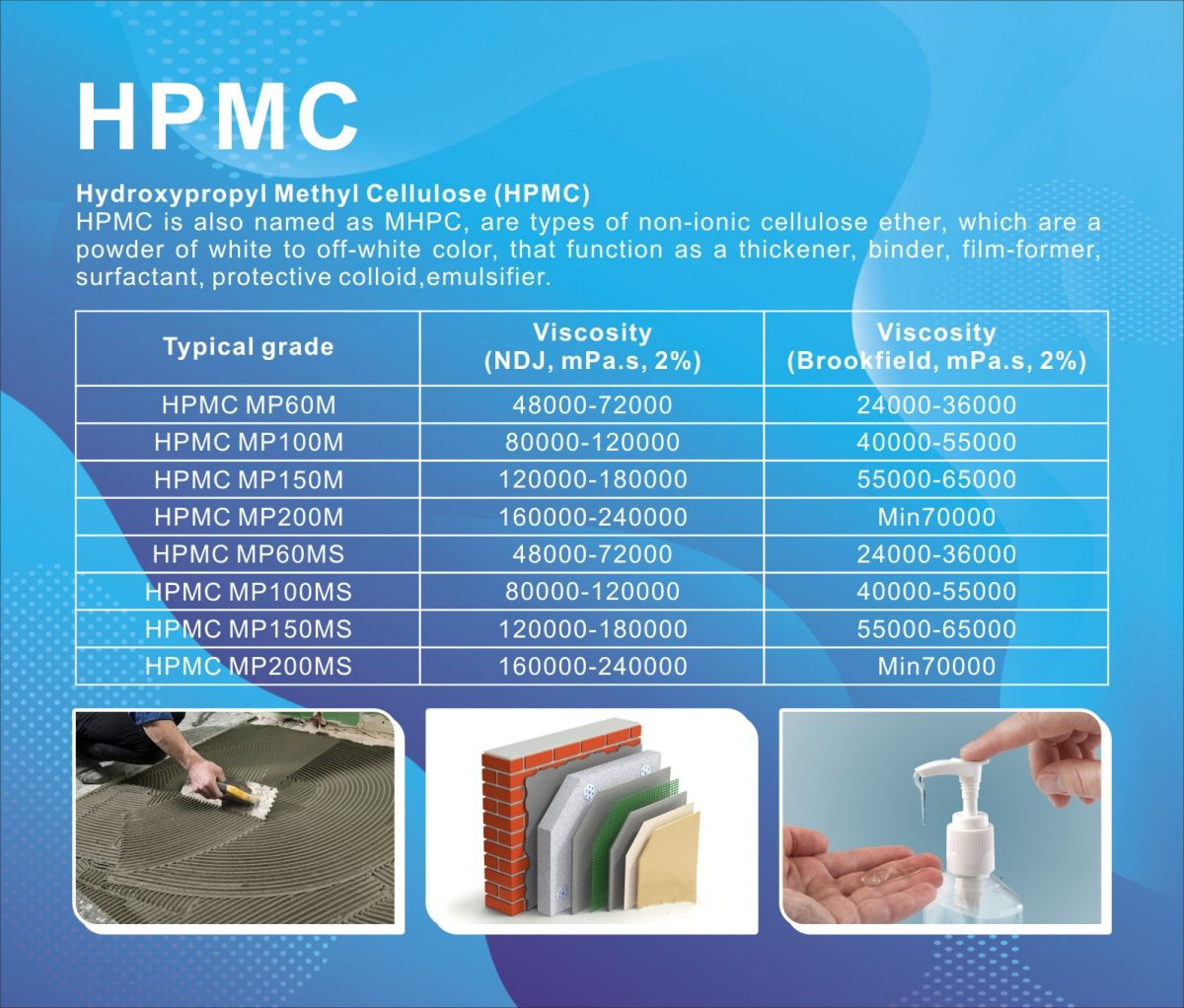

Additives are used to modify and enhance the properties of the dry mixed mortar. These can include cellulose ethers accelerators, retarders, plasticizers, air-entraining agents, and more. Additives are added in relatively small quantities but have a significant impact on the mortar’s workability, setting time, and performance under different conditions.

2.4. Water

Water is a vital component that facilitates the mixing of the dry ingredients, allowing them to form a workable paste. The water-to-cement ratio is crucial, as it affects the mortar’s consistency, setting time, and overall performance.

3. The Formulation Process

The formulation of dry mixed mortar involves carefully weighing and mixing the components in the right proportions. The process begins with the selection of raw materials, including the choice of fine aggregate, cementitious binders, additives, and water. Once the materials are selected, they are batched according to the desired recipe.

The dry components (fine aggregate and cementitious binders) are first mixed to achieve a homogeneous blend. Afterward, additives and water are incorporated into the mixture. The mixing process may vary depending on the specific formulation and the equipment used. Proper mixing is essential to ensure uniform distribution of all components, which directly affects the mortar’s quality and performance.

4. Factors Affecting Formulation

The formulation of dry mixed mortar is influenced by several factors, including application requirements, environmental conditions, and cost considerations.

4.1. Application Requirements

Different construction projects have varying requirements for dry mixed mortar. Factors such as strength, durability, setting time, and color may differ based on the application. Formulations are adjusted to meet these specific needs. For example, mortar used in masonry construction requires different properties than mortar used in tile installation.

4.2. Environmental Conditions

Environmental conditions, such as temperature and humidity, can impact the formulation process. These factors affect the mortar’s setting time and workability. In extreme conditions, special formulations may be needed to ensure proper mortar performance.

4.3. Cost Considerations

The cost of materials and the overall production process can influence formulation decisions. Adjusting the formulation to optimize cost-effectiveness while maintaining performance is a critical consideration for manufacturers.

5. Quality Control

Quality control is a crucial aspect of dry mixed mortar production. Ensuring consistent product quality is essential to meet industry standards and customer expectations.

5.1. Testing and Analysis

Manufacturers conduct various tests and analyses on both raw materials and the final mortar product. These tests assess properties such as compressive strength, adhesive strength, workability, and durability. Adjustments to the formulation may be necessary based on the test results.

5.2. Batch-to-Batch Consistency

Maintaining consistency from one batch to another is vital for quality control. Deviations in the formulation can lead to inconsistent product performance. Stringent quality control measures help avoid such inconsistencies.

6. Common Dry Mixed Mortar Formulations

Different applications in construction require specific mortar formulations. Here are some common dry mixed mortar formulations and their key properties:

6.1. Masonry Mortar

Masonry mortar is used in brick or block construction. It typically consists of sand, cement, and sometimes lime. The formulation is designed to provide good workability, strong adhesion, and resistance to weathering.

6.2. Plaster Mortar

Plaster mortar is used for interior and exterior plastering of walls and ceilings. It is formulated to provide a smooth and durable finish. Additives like retarders may be used to extend the setting time for plaster application.

6.3. Tile Adhesive

Tile adhesive mortar is designed for affixing tiles to various surfaces. It requires strong adhesion and excellent workability. Polymer additives are often included to enhance bonding and flexibility.

6.4. Self-Leveling Mortar

Self-leveling mortar is used to create level surfaces on uneven substrates. It flows easily and levels itself, ensuring a smooth and even finish. Additives such as superplasticizers are used to achieve the desired flow properties.

6.5. Repair Mortar

Repair mortar is formulated for patching and repairing damaged concrete or masonry surfaces. It provides high strength and excellent bonding to the existing substrate. Corrosion inhibitors may be added for enhanced durability.

6.6. Insulation Mortar

Insulation mortar is used in external thermal insulation systems (ETICS) to attach insulation boards to walls. It has specific properties to ensure the thermal performance of the insulation. Lightweight aggregates are often incorporated to reduce heat transfer.

7. Conclusion

Dry mixed mortar formulation is a complex process that involves the precise combination of fine aggregate, cementitious binders, additives, and water to create a construction material tailored to specific applications. Understanding the role of each component and considering factors such as application requirements, environmental conditions, and cost is crucial in producing high-quality dry mixed mortar. Quality control measures ensure consistent product performance and meet industry standards. The use of dry mixed mortar formulations is widespread in various construction applications, from masonry and plastering to tile adhesive and insulation systems, highlighting its importance in the modern construction industry.

8. References

Please note that the table containing specific dry mixed mortar formulations for various applications has been omitted from this response due to its extensive nature. If you would like a detailed table, please provide specific details regarding the formulations you are interested in, and I can assist you in creating a table based on that information.

Post time: Nov-10-2023