Ntsiab lus: hydroxypropyl methyl cellulose; PVC nrog siab polymerization degree; kev sim me me; polymerization; localization.

Daim ntawv thov ntawm Tuam Tshoj Hydroxypropyl methylcellulose yog ib qho khoom siv zooes tsis txhob imported ib mus rau zus tau tej cov PVC nrog siab polymerization degree tau qhia. Cov teebmeem ntawm ob hom hydroxypropyl methylcellulose ntawm cov khoom ntawm PVC nrog high polymerization degree tau tshawb xyuas. Cov txiaj ntsig tau pom tias nws muaj peev xwm hloov cov khoom siv hauv tsev hydroxypropyl methyl cellulose rau cov khoom tuaj.

High-degree-of-polymerization PVC resins xa mus rau PVC resins nrog ib tug nruab nrab degree ntawm polymerization ntawm ntau tshaj 1,700 los yog ib tug me ntsis cross-linked qauv ntawm molecules. Piv nrog cov PVC zoo tib yam, high-polymerization PVC resin muaj siab resilience, me compression teeb, zoo tshav kub tsis kam, laus kuj, qaug zog thiab hnav tsis kam. Nws yog ib qho zoo tagnrho hloov roj hmab thiab tuaj yeem siv rau hauv tsheb sealing strips, xaim thiab cable, catheters kho mob, thiab lwm yam.

Txoj kev tsim khoom ntawm PVC nrog qib siab ntawm polymerization yog tsuas yog ncua kev kawm ntawv polymerization. Nyob rau hauv kev tsim cov txheej txheem ncua kev kawm ntawv, cov dispersant yog ib tug tseem ceeb pab neeg sawv cev, thiab nws cov hom thiab cov nyiaj yuav ncaj qha cuam tshuam rau particle zoo, particle loj tis, thiab plasticizer nqus ntawm cov tiav PVC resin. Cov tshuab dispersion feem ntau yog polyvinyl cawv tshuab thiab hydroxypropyl methylcellulose thiab polyvinyl cawv composite dispersion systems, thiab domestic manufacturers feem ntau siv tom kawg.

1 Main raw khoom thiab specifications

Cov ntaub ntawv tseem ceeb thiab cov kev qhia tshwj xeeb uas siv hauv qhov kev xeem tau pom nyob rau hauv Table 1. Nws tuaj yeem pom los ntawm Table 1 tias cov khoom siv hauv tsev hydroxypropyl methylcellulose tau xaiv hauv daim ntawv no yog ua raws li cov khoom siv los ntawm hydroxypropyl methylcellulose, uas yuav tsum tau ua ua ntej rau kev hloov pauv hauv qhov no. ntawv.

2 Test cov ntsiab lus

2. 1 Kev npaj ntawm hydroxypropyl methylcellulose tov

Siv ib co dej deionized, muab tso rau hauv ib lub thawv thiab kub rau 70 ° C, thiab maj mam ntxiv hydroxypropyl methylcellulose nyob rau hauv tas li stirring. Cov cellulose ntab saum dej thaum xub thawj, thiab tom qab ntawd maj mam sib cais kom txog thaum nws sib npaug. Txias qhov kev daws rau ntim.

Table 1 Cov ntaub ntawv tseem ceeb thiab lawv cov specifications

| Raw khoom npe | Specification |

| Vinyl chloride monomer | Cov qhab nia zoo ≥ 99. 98% |

| Desalinated dej | Conductivity ≤10. 0 μs / cm, pH tus nqi 5.00 txog 9.00 |

| Polyvinyl cawv A | Alcoholic degree 78. 5% rau 81. 5%, hmoov tshauv ≤0. 5%, qhov teeb meem tsis haum ≤5. 0% |

| Polyvinyl cawv B | Alcoholic degree 71. 0% rau 73. 5%, viscosity 4. 5 txog 6. 5mPa s, volatile matter≤5. 0% |

| Polyvinyl cawv C | Alcoholic degree 54. 0% rau 57. 0%, viscosity 800 ~ 1 400mPa s, cov ntsiab lus khoom 39. 5% mus rau 40.5% |

| Imported hydroxypropyl methylcellulose A | Viscosity 40 ~ 60 mPa s, methoxyl pawg feem 28% ~ 30%, hydroxypropyl pawg feem 7% ~ 12%, noo noo≤5. 0% |

| Hauv tsev hydroxypropyl methylcellulose B | Viscosity 40 ~ 60 mPa · s, methoxyl pawg feem 28% ~ 30%, hydroxypropyl pawg feem 7% ~ 12%, noo noo ≤5. 0% |

| Bis (2-ethyl peroxydicarbonate) Hexyl ester) | Loj feem [(45 ~ 50) ± 1]% |

2. 2 Test method

Ntawm 10 L cov cuab yeej ntsuas me me, siv cov khoom siv los ntawm hydroxypropyl methylcellulose los ua cov qauv ntsuas ntsuas los txiav txim siab cov qauv ntawm qhov ntsuas me me; siv cov hydroxypropyl methylcellulose hauv tsev los hloov cov khoom siv hydroxypropyl methylcellulose los kuaj; Cov khoom siv PVC ua los ntawm hydroxypropyl methylcellulose tau muab piv, thiab qhov ua tau los hloov cov khoom siv hauv tsev hydroxypropyl methylcellulose tau kawm. Raws li cov txiaj ntsig ntawm qhov kev sim me me, kev sim ntau lawm yog ua tiav.

2. 3 Cov kauj ruam xeem

Ua ntej cov tshuaj tiv thaiv, ntxuav lub polymerization kettle, kaw hauv qab valve, ntxiv ib tug npaum li cas ntawm desalinated dej, thiab ces ntxiv dispersant; kaw lub hau npog, nqus tsev tom qab dhau qhov kev sim siab nitrogen, thiab tom qab ntawd ntxiv vinyl chloride monomer; tom qab txias nplawm, ntxiv cov pib; Siv cov dej ntws los ua kom qhov kub thiab txias hauv lub lauj kaub rau qhov kub thiab txias, thiab ntxiv cov tshuaj ammonium bicarbonate raws sij hawm thaum tus txheej txheem no los kho pH tus nqi ntawm cov tshuaj tiv thaiv kab mob; thaum cov tshuaj tiv thaiv siab poob mus rau lub siab teev nyob rau hauv cov mis, ntxiv ib tug terminator thiab ib tug defoamer, thiab tso cov tshuaj. Cov khoom tiav ntawm PVC resin tau txais los ntawm centrifugation thiab ziab, thiab coj mus kuaj.

2. 4 Txoj kev tsom xam

Raws li cov txheej txheem ntsuas cuam tshuam hauv Enterprise tus qauv, ceev tus lej, nrawm dua ntawm 100 g pvc resin ntawm ua tiav pvc resin tau sim thiab txheeb xyuas; Qhov nruab nrab particle loj ntawm PVC resin raug kuaj; Lub morphology ntawm PVC resin hais tau pom siv lub tshuab ntsuas hluav taws xob scanning.

3 Cov txiaj ntsig thiab kev sib tham

3. 1 Kev sib piv ntawm qhov zoo ntawm cov khoom sib txawv ntawm PVC cob hauv me me-polymerization

Xovxwm 2. Raws li txoj kev xeem uas tau piav nyob rau hauv 4, txhua batch ntawm cov khoom me me ua tiav PVC resin raug kuaj, thiab cov txiaj ntsig tau qhia hauv Table 2.

Table 2 cov txiaj ntsig ntawm cov khoom sib txawv ntawm kev sim me me

| Batch | Hydroxypropyl methylcellulose yog siv | Pom tseeb qhov ceev / (g / mL) | Qhov nruab nrab particle loj / μm | Viscosity / (mL / g) | Plasticizer nqus ntawm 100 g PVC resin / g | Tsis muaj teeb meem /% |

| 1# | Ntshuam | 0.36 ib | 180 | 196 | 42 | 0.16 |

| 2# | Ntshuam | 0.36 ib | 175 | 196 | 42 | 0.20 ib |

| 3# | Ntshuam | 0.36 ib | 182 | 195 | 43 | 0.20 ib |

| 4# | Hauv tsev | 0.37 ib | 165 | 194 | 41 | 0.08 ib |

| 5# | Hauv tsev | 0.38 ib | 164 | 194 | 41 | 0.24 ib |

| 6# | Hauv tsev | 0.36 ib | 167 | 194 | 43 | 0.22 |

Nws tuaj yeem pom los ntawm rooj 2: Tus lej dav dav, tus naj npawb viscosity thiab cov yas resining ntawm tau txais cov partulose los ntawm kev siv cellulose txawv rau kev kuaj me me; cov khoom siv cob tau los ntawm kev siv cov mis hydroxypropyl methylcellulose hauv tsev Qhov nruab nrab particle loj me me.

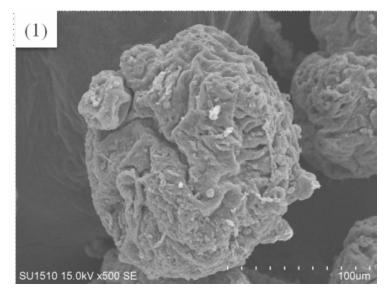

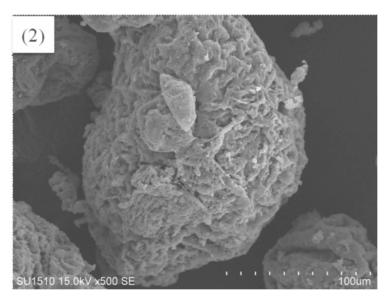

Daim duab 1 qhia txog SEM cov duab ntawm PVC resin khoom tau los ntawm kev siv cov hydroxypropyl methylcellulose sib txawv.

(1) - Imported hydroxypropyl methylcellulose

(2) - Hauv tsev hydroxypropyl methylcellulose

Fig. 1 SEM ntawm resins ua nyob rau hauv 10-L polymerizer nyob rau hauv muaj sib txawv hydroxypropyl methyl cellulose

Nws tuaj yeem pom los ntawm daim duab 1 tias cov txheej txheem saum npoo ntawm PVC cov khoom ua los ntawm cov cellulose dispersants sib txawv kuj zoo ib yam.

Ua kom tiav, nws tuaj yeem pom tau tias cov khoom siv hauv tsev hydroxypropyl methylcellulose kuaj hauv daim ntawv no muaj qhov ua tau los hloov cov khoom siv hydroxypropyl methylcellulose.

3. 2 Kev txheeb xyuas qhov zoo ntawm PVC cob nrog siab polymerization degree hauv kev xeem ntau lawm

Vim yog tus nqi siab thiab kev pheej hmoo ntawm kev sim ntau lawm, kev hloov pauv ntawm qhov kev sim me me tsis tuaj yeem siv ncaj qha, yog li txoj kev npaj yuav maj mam nce qhov feem ntawm domestic hydroxypropyl methylcellulose hauv cov mis. Cov txiaj ntsig kev xeem ntawm txhua batch muaj nyob rau hauv Table 3 qhia.

Table 3 Cov qhabnias ntawm cov khoom sib txawv

| Batch | m (Tuam Tshoj hydroxypropyl methyl cellulose): m (ntsuas hydroxypropyl methyl cellulose) | Pom tseeb qhov ceev / (g / mL) | Viscosity naj npawb / (mL / g) | Plasticizer nqus ntawm 100 g PVC resin / g | Tsis muaj teeb meem /% |

| 0# | 0: 100 | 0.45 ib | 196 | 36 | 0.12 |

| 1# | 1.25: 1 | 0.45 ib | 196 | 36 | 0.11 |

| 2# | 1.25: 1 | 0.45 ib | 196 | 36 | 0.13 |

| 3# | 1.25: 1 | 0.45 ib | 196 | 36 | 0.10 |

| 4# | 2.50: 1 | 0.45 ib | 196 | 36 | 0.12 |

| 5# | 2.50: 1 | 0.45 ib | 196 | 36 | 0.14 ib |

| 6# | 2.50: 1 | 0.45 ib | 196 | 36 | 0.18 |

| 7# | 100: 0 | 0.45 ib | 196 | 36 | 0.11 |

| 8# | 100: 0 | 0.45 ib | 196 | 36 | 0.17 ib |

| 9# | 100: 0 | 0.45 ib | 196 | 36 | 0.14 ib |

Nws tuaj yeem pom los ntawm Table 3 tias kev siv hauv tsev hydroxypropyl methyl cellulose yog maj mam nce mus txog thaum lub tsev hydroxypropyl methyl cellulose hloov pauv cov khoom siv hydroxypropyl methyl cellulose. Cov cim tseem ceeb xws li plasticizer absorption thiab pom tseeb qhov ntom ntom tsis hloov pauv loj, qhia tias cov khoom siv hydroxypropyl methylcellulose hauv tsev tuaj yeem hloov pauv cov khoom siv hydroxypropyl methylcellulose tuaj.

4 Kev xaus

Qhov kev sim ntawm domestic hydroxypropyl methyl cellulose ntawm 10 L cov cuab yeej ntsuas me me qhia tau tias nws muaj peev xwm hloov tau cov khoom siv hydroxypropyl methyl cellulose; Cov txiaj ntsig kev hloov pauv ntau lawm qhia tau hais tias hauv tsev hydroxypropyl methyl cellulose yog siv rau PVC resin ntau lawm, lub ntsiab zoo ntawm PVC resin tiav thiab imported hydroxypropyl methyl cellulose tsis muaj qhov sib txawv loj. Tam sim no, tus nqi ntawm domestic cellulose nyob rau hauv kev ua lag luam yog qis dua li ntawm imported cellulose. Yog li ntawd, yog hais tias domestic cellulose yog siv nyob rau hauv ntau lawm, tus nqi ntawm kev pab ntau lawm yuav txo tau ho.

Post lub sij hawm: Nov-04-2022